Is there quite a lot of loads which are loaded on pallets need to be wrapped everyday in your warehouse or the workshops? The turntable pallet stretch wrapper might be a machine which you should consider, because they can help you to finish the stretch wrapping more quickly with great efficiency and capability. Avoid the injuries such as back injury due to the heavy work when wrapping by hands manually.

The technology of this machine is rotating the pallet loads on the turntable and applying the stretch film to the pallets simultaneously. the film roll is loaded on the film carriage which travels up and down to cover the whole load with completed wrapping.

To be specific, there are actually two types of turntable pallet stretch wrappers, the semi-auto model and fully automatic model. Each model has their advantage and disadvantages. We will bring you to know better about it below:

Semi-Automatic Turntable Pallet Wrapper

The semi-auto model of turntable pallet stretch wrapper has to be operated by an operator, the machine will wrap the pallet automatically but the loading and unloading should be down by the operator with pallet jack or forklift. The machine also requires the operator to have a press on the start button before starting the wrapping.

After the wrapping is down, it’s also required to cut the film manually, excepts some models may include an automatic film cutter which will do the film loading, clamping, cutting automatically. Although it’s not fully automatic, but the wrapping process is very time consuming and heavy. So the semi-auto model is still popular as it can give great help and improve your capacity. Plus, the machine has pre-stretch function which saves material and make tighter wrapping package than the manual wrapping.

The general speed of the semi-auto model is about 10-30 pallets per hour, still and ideal machine to improve your loadability and reduce the product damage and save money on the wrapping material.

Fully Automatic Turntable Pallet Stretch Wrapper

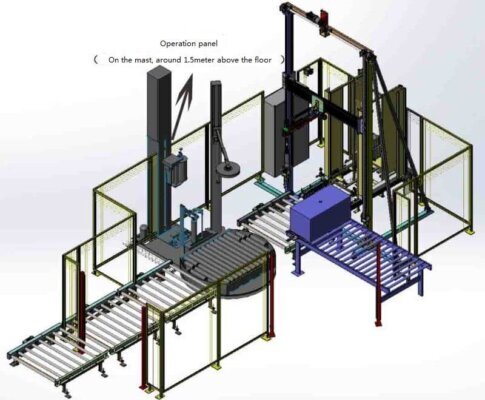

From the name of this model, we can see the this model is unmanned operation which do not require a specific operator. The machine is integrated with palletizer or assembling and packaging line by conveyors. When the machine detects the incoming loads of pallets, it will start the conveying and wrap the pallets at the turntable position. Automatic film clamping and cutting will be down by the film clamp after the wrapping and every step is controlled by the PLC program without the need for any operators.

The Conclusion

After the introduction of all the advantages of these two models, we can see it’s ideal for small business owners to choose the semi-auto turntable pallet stretch wrapper as they have lower quantity and want to spend less on the machinery. But it’s might necessary for the big plants and warehouses to have the fully automatic turntable pallet stretch wrapper. Because they also have the existing line of assembling or packaging and integrate the pallet wrapper machine with the other machinery can make the whole progress automated. This not just improved their capacity and working time, but also save a lot on the labor costs and reliable on their production line.