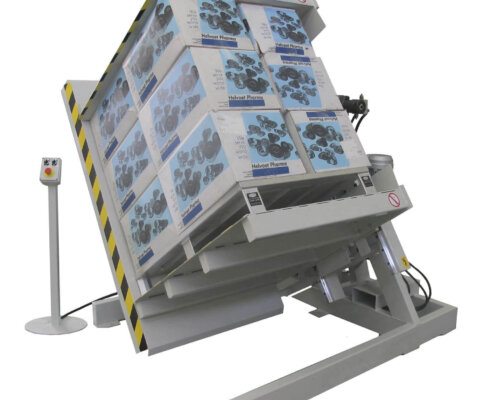

180 degree pallet inverter machine application of industry: widely used in various industries such as metallurgy, machinery, steel, oil field, dock, ocean transportation, electric power, automobile manufacturing, ship building, railway, aviation, military industry and so on. If your goods are stacked on a pallet and require a 180-degree turning, you can use this 180-degree pallet inverter machine to turn it over.

There are plastic pallets on the bottom and pages of the goods:

1. Use a motorized forklift to place the goods on the worktable of the pallet turning machine;

2. Manually clamp the cargo and flip it up to the safe flipping range;

3. Turn the pallet with the goods-up and down 180 degrees;

4. Loosen the splint;

5. Return the turning machine;

6. Remove the goods with the pallet from the pallet changing machine with a motorized forklift;

7.Remove the top plastic tray;

Safety protection measures:

Equipped with safety grating, if forklift or people are in the working area, the equipment will automatically alarm without turning over. Multiple limit protection, safety guarantee, equipped with mechanical limit device, if the electronic control fails, it can also ensure the absolute safety of the machine and the operator. And the device has an overweight limit function.

Equipment technical requirements and instructions:

1. Use a motorized forklift to in and out of goods, multi-speed vector control, stable and reliable.

2. Electromagnetic brake motor, if there is a power failure during the turning process, the machine will automatically lock and stop rotating, and there will be no reverse situation.

3. The product flip angle can be adjusted less than 180 degrees to effectively prevent the product from tipping over.

4. Pneumatic components and all bearings are selected from domestic well-known professional manufacturers.

5. It can work in a 180-degree cycle in the forward and reverse directions.

6. Reasonably designed transmission mechanism box, manual operation, cyclical work.

7. The use of an independent control cabinet improves the operability and maintainability. 5-10M line control operation is adopted between the operation box and the host.