Evaporative cooling is the ideal and most economical method of cooling. It’s a process that uses the evaporation of water on the surface of a wet pad to remove heat from the air for cooling. By passing hot fresh air through an evaporative cooling pad, a temperature reduction of 10 to 20°C can be achieved.

The effectiveness of evaporative cooling depends on the dry-bulb and wet-bulb temperatures of the surrounding air, the thickness of the wet pad, the geometry of the wet pad, and the speed of air passing through the wet pad. At the same time, it is also necessary to continuously supply appropriate water and ensure even distribution of water so that all parts of the wet pad are moistened in all directions. The hotter and drier the incoming air is, the more significant the temperature drop will be after passing through the wet pad.

An evaporative cooler is a device that uses this principle to cool air by evaporating water. Unlike typical air conditioning systems, which use a vapor compression or absorption refrigeration cycle. Evaporative cooling takes advantage of the fact that water absorbs relatively large amounts of heat to evaporate. Through the phase change of liquid water to water vapor, the temperature of dry air can be reduced significantly. This uses less energy to cool the air compared to air conditioners. At the same time, in extremely dry climates, another benefit of air evaporative cooling is that it can adjust the humidity of the air to make users feel comfortable.

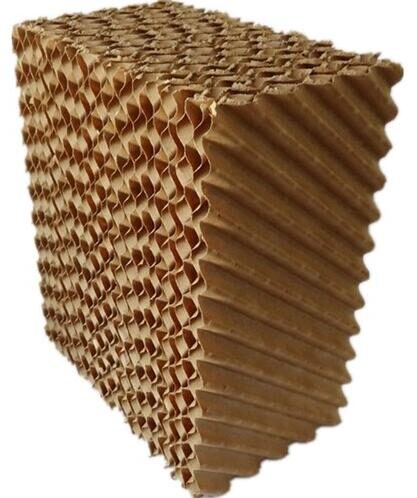

The air coolers, water-cooled air conditioners and other products currently sold on the market are actually evaporative coolers as well, just the sellers gave them a nice-sounding, high-end product name. In the hot summer, its sales can often reach shocking levels. The core material of the evaporative cooler is the wet pad(evaporative cooling pad). Since it is mostly installed vertically inside the machine, it is also called a wet curtain.

The wet curtain is made of corrugated fiber bundles pressed at a 45° angle and bonded together in the cross direction of the corrugations. The wet curtain uses velvet material with special hygroscopicity and adopts advanced processing technology. Special chemicals that are not decomposed by water are added to the raw materials, so it has superior water absorption, moisture stiffness, corrosion resistance and service life. The porous structure facilitates the rapid circulation of air and improves the cooling effect of the evaporative cooler.

When we make the package of the evaporative cooling pads, we need to consider some physical properties of this material. Its porous structure is the key, so we can not deform it any way. And it’s easy to absorb moisture, so we need to make an airtight package to keep it dry.

The side seal shrink wrap machine is good for making small packages of evaporative cooling pads

It’s fast to form a bag on the bundles, make a seal and shrink the package to tight condition, avoid dust, vapor and rain. Suitable for packaging the evaporative cooling pads in single layer or multiple layers with limited heights.

Over lap seal shrink wrap machine is the ideal solution for packaging big bundles of evaporative cooling pads

This machine has customized forming molds to wrap the big bundles of evaporative cooling pads, seals the package at the bottom over lapping area. Available for large bundles with big width and heights.