The stretch hooder machine is a new type of high-efficiency pallet wrapping equipment that is not limited to categories. It can automatically and continuously cut and seal large and tall stacked bulk products, such as stacked bottled drinks, stacked bags of grain or cement, stacked furniture, stacked chemical raw materials, etc. Traditional pallet shrink packaging machine requires heat shrink equipment when used, consumes too much energy, and is not very safe with the flames. However, the efficiency of pallet stretch wrapping machine is low, and the packaging appearance quality has many defects, which cannot meet the needs of users.

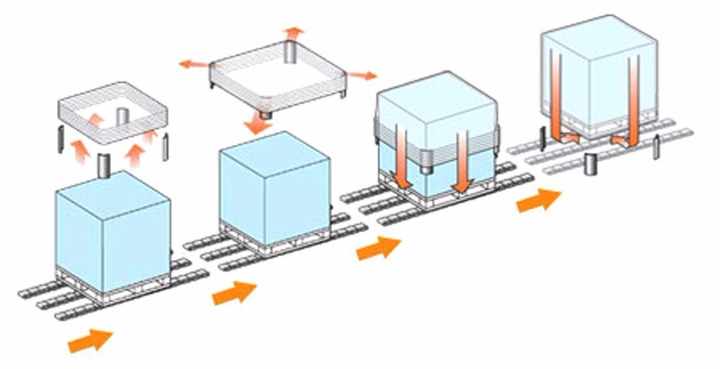

The stretch hooder machine can quickly adjust the automatic film feeding, automatic bag making, automatic feeding, automatic sealing and replacement of different products in film packaging. By adjusting the original film packaging methods and materials, the packaging can be made more efficient, strong and beautiful. At the same time, it can also save more energy. Multiple adjustment mechanisms enable items of different specifications to be packaged in the best possible condition.

Comparison with Heat Shrink Wrap Machine

- Adaptive packaging effects. The stretch hooder uses elastic film with extremely strong clamping force, which can automatically adapt to the size of the goods. In contrast, heat shrink wrap machine uses gas heat to shrink the film at high temperatures, so it will adhere to the product;

- Save energy and packaging material. As there is no gas used, stretch hooder consumes less energy than shrink wrap machine, and the film required for stretch hood wrapping machine is smaller than the size of the goods, while heat shrink wrap machine requires a larger film, so waste of film is avoided and environmental pollution is significantly reduced;

- Greater security. Stretch hood packaging does not involve any form of heating and therefore avoids the fire or explosion hazards inherent in gas-fired appliances;

- Greater adaptability. Stretch hood packaging can use various power sources according to needs, such as electricity, hydraulic or pneumatic, while heat shrink packaging can only rely on gas to quickly provide heat, or slower electric heating;

- Packaging time is faster. Stretch hood packaging avoids the heat shrink packaging preparation stage, so the packaging speed is faster, reaching a production level of 150 pallets/hour at the fastest;

- Improved packaging quality. The finished product packaged by stretch hood machine has a perfect appearance without wrinkles. Additionally, since no heating is required, the product and film do not stick to each other;

- Can be adapted to non-heatable products. For products such as fresh vegetables, milk, cooked food, or thermal paper, high temperatures will affect product quality. No heating is used in the stretch hood packaging process, so it is very suitable for packaging of various products that are sensitive to heat sources;

- Higher stability packaging. Due to the large vertical stretching force of the film, the loadability is improved;

- The film is completely reusable. The film used in stretch hood packaging is made of better material and is relatively thicker. When opening the package, you only need to make a cut to take out the product. The relatively intact film also makes its recycling feasible.