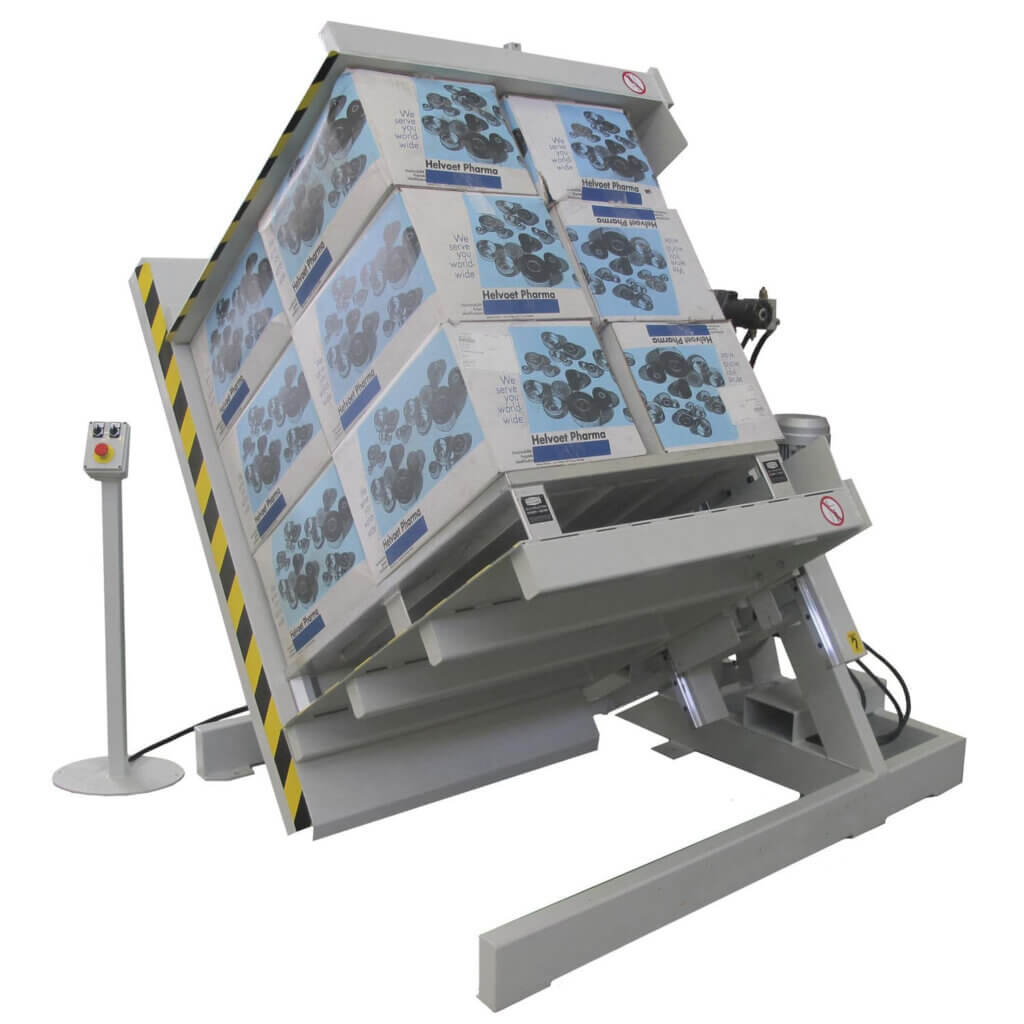

Pallet changer is a very practical machine to turn goods upside down and it’s widely used in the loads inverting process in big warehouses.

It’s working on the floor level which convenient for loading and discharging the palletized goods by a pallet truck for forklift.

The machine is special to tip the pallets separately with the bottom platen driven by an individual cylinder. This design makes it easy to exchange the pallets ergonomically without handling the pallets by any manual work.

This pallet changer has two side panels to clamp the loads before tilting. The machine can turn the whole load backwards to 110°. It’s more often used for sensitive and less dimensionally stable goods.

Different from the upper model, this pallet changer is helding the palletized goods on three sides. It’s a suitable machine to used for overhang goods like sacks, big bags and drums. The pallet inverter will turn the entire stack upside down by 180°, the bottom pallet then will turn to be on top and easy to replace, or operator can directly take the entire stack out after inverting and only has to lift off the old pallets. Some users also use this machine to make 90° turnover in order to exchange pallets in vertical position. It’s easy and efficient to use, but there is also a drawback of this machine which is the pallet’s orientation can not be promised.

So no matter how does the pallet changer work or in which design, we ought to choose the model which is more suitable for your use depending on your needs and individual requirements.

As manufacturer, we always dedicated on new technology and design to help our customers maximize their capacity.