When it comes to protecting a product, or keeping it fastened and intact for shipping; stretch and shrink wrap is commonly used. Although these two packages have many differences, people often get confused about them. Here is an overview of the differences between these two packaging ways and the applications they are used.

Stretch wrap

Stretch wrap is a stretchable plastic film that is wrapped around a stack of products, allowing it to stretch; this elasticity holds the load tightly together.

What’s the material?

Most commonly made of polyethylene plastic.

Where does it apply to?

This type of packaging is often used to secure goods and products together on pallets for shipping or storage purposes. It uses variant packaging materials including: PVC Stretch Films, LLDPE stretch film, Anti-Static Stretch Films, Colored Stretch Films, Anti-Rust Stretch Films, etc.

Characteristics:

Protective – This packaging is safe and protects the product from dust and moisture. It can also be protected from sunlight with a UV film option

Cost Effective – Stretch wrap is less expensive than other types of packaging. Additionally, the equipment for stretch wrapping is less expensive than other forms of packaging.

Adaptable – Stretch film is available in a variety of films to suit a variety of applications; it’s even suitable for different types of surfaces.

Applicable machines:

Hand wrapping tools include an expanding core and a film extension that acts as a handle. Mechanical brakes have a supporting structure with a braking system. The rod wrapper includes an extended rod for ease of use.

A stretch wrapper is recommended when wrapping more than 15 items per day. Stretch wrapper helps reduce waste and increase efficiency.

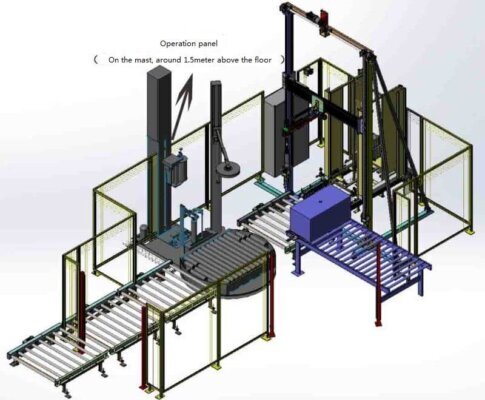

Semi-automatic wrapper includes turntable wrappers, where loads are placed on a carousel and wrapped by a vertically moving film carriage. Rotary arm wrappers rotate around a stationary load for wrapping. Spiral wrappers involve feeding a load through a rotating film ring.

Automatic wrappers involve conveyors and machines to cut and sweep the stretch wrap automatically.

What’s the material?

Most commonly made of polyolefin plastic.

Where does it apply to?

This type of packaging is often used to protect individual products from dust or the weather; or to hold smaller items close together. It can also pack products together on pallets; but less commonly. This type of packaging is widely used to wrap food and grocery; for instance: instant noodels, vegetables and bottled water.

Characteristics:

Protective – Shrink wrap is great for protecting products from air or moisture, as well as dust and dirt.

No surface damage – If the shrink wrap has been applied correctly, there should be no problems with chafing or damage during shipping or storage.

Breathability – The shrink wrap has the option of being ventilated; thus reducing any damage that moisture might cause.

Applicable machines:

A heating machine is essential when working with any type of shrink wrap.

Some shrink wrap machines that can be used with shrink tunnels mounted above or around the conveyor system for the product to go through the ovens.

Many automatic and manual shrink wrap machines are also available, such as the L-Bar sealer shrink wrapper and Sleeve sealing shrink wrapping machines.

Most shrink wrap machine can cut and weld the shrink film together; once done, heat can be applied to shrink the plastic and secure it to the product.