Stretch film wrapping machines generally use pre-stretch film carriage to stretch the film and then wrap it on the goods. However, the structure of this film carriage is fixed. If you want to insert the stretch film into the film carriage, you must pull the stretch film back and forth between the small gap of the rollers by hand. Once you make a mistake, it is easy to cause hand injury, and once the stretch film turns back, you must stop the machine and do cleaning work in a small space. Therefore, there are shortcomings such as low efficiency and poor safety performance.

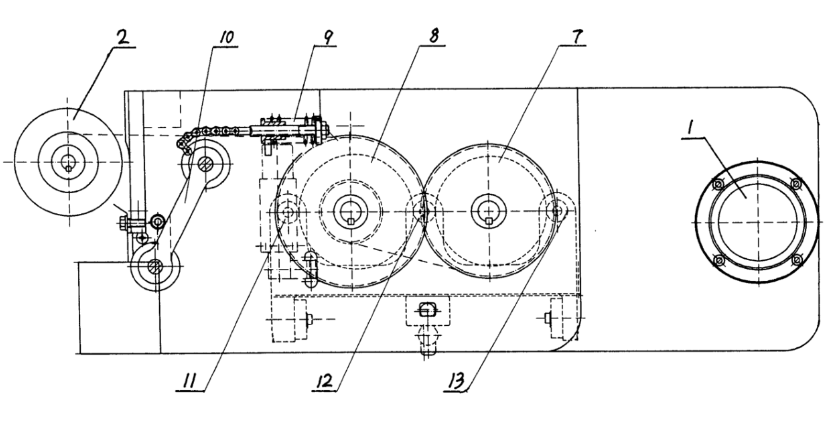

The open-door pre-stretch film carriage consists of a lower plate, an upper plate, a film tube, a door opening device, a motor, a transmission mechanism, a driving roller, a reduction device, a driven roller and a guide roller. The motor communicates with the film carriage through the transmission mechanism. The driving roller is connected to the driven roller through a deceleration device. The door opening device is installed on the lower plate of the film carriage, and the guide roller is installed on the door opening device. When the door opening device is opened, each guide roller leaves the driving roller and the driven roller, and the film penetration operation can be performed. During this process, the door opening device is in a power-off state. When the door opening device is closed, each guide roller contacts the driving roller and the driven roller, and transmits a signal to the motor to perform the stretching operation. Easy to operate and good safety performance.

When working, put the stretch film on the film tube 1, open the door opening device 14, and penetrate into the film carriage according to the operation shown in Figure. The motor generates power. The driving roller 8 and the driven roller 7 are driven to rotate. Since the rotation speed of the driving roller 8 is higher than that of the driven roller 7, a speed difference is generated. The linear speed of the stretched film when passing through the driving roller 8 and the driven roller 7 is different. The front end of the stretch film has a high running degree and the rear end running degree is low. , so that the stretch film itself is subjected to tensile force, producing a stretching effect.

Only when the door opening device is closed, the limit switch can be closed, transmit a safety signal to the control device, and start the motor. In addition, when the goods pull the film and cause it to rotate away from the original position, the swing arm will send the control signal to the control system through the switch to start the motor, ensuring that the film feeding system will not active when the whole wrapping machine is not running. All these devices ensure that the entire operation process is completely under control.

This new type of pre-stretch film carriage not only ensures the stretching effect, but also ensures that the stretch film will never come out of the film carriage, improve the overall safety performance of the stretch film wrapping equipment.