In this fast-developing information age, all walks of life are developing rapidly, and the pace of life and production is obviously accelerating. In modern production, in the face of various demands, whoever can take the lead in speed and improve production efficiency will be able to seize the opportunities of the times.

There is also a collision of speed and passion in the field of automatic packaging at the back end. Complete a complete set of wrapping packaging process of “pallet input-product pre-stretch wrapping-automatic film breaking-pallet output” within 0.8 minutes; complete wrapping process of 60 to 80 pallets within 1 hour; pre-stretching that combines efficiency and benefit concepts The stretch design saves at least 30% of the stretch film material in achieving a tight and beautiful wrapping effect.

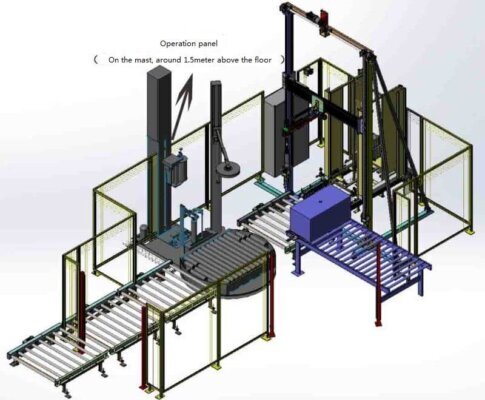

The 360-degree orbital ring body design is adopted to this ring type pallet packaging machine. The pre-stretching film frame system is separated from the stretching power device. The pre-stretching power system adopts a lightweight synchronous belt drive and a sliding contact line power supply system for stable output.

The vertical lifting system uses linear slide rails + double-sided positioning guide wheels + elastic auxiliary positioning guide wheels to perform three-way correction and positioning of the lifting track; the horizontal rotation system uses U rotating rails + horizontal positioning guide wheels + vertical two-way positioning guides The wheel sets the horizontal rotation track for three-way correction and positioning. The lifting and rotating system is as stable and free as high-speed rail travel, and never derails.

The ring type pallet wrapping machine adopts a constant-temperature hot film method to realize automatic film breaking. The conventional film breaking method is often to set a fixed time, such as 2-3 seconds to break the stretch film by heating. However, due to different factors such as the working environment and the quality of the membrane, the effects are not the same.

Constant temperature hot film technology, through the temperature controller to accurately control the temperature suitable for film breaking. Its outstanding feature is that the film tail at the broken film is short, the dissolution strength is high, and the viscosity is strong.

Speed and safety have never been a contradiction. Mechanical limit of extreme position, configuration of safety relay (Safety relay), safe torque off (STO), interlocking linkage safety control system. Not only to ensure that the packaging effect is flawless, but also to ensure the safety and error-free operation.