The Aluminum profile packaging line is a machine that has fully automatic control system with the PLC and sensors. It’s available to connect with user’s extrusion lines to make a n integrated packing line for inline operation. The line will greatly reduce the man power and labour cost for the packaging. Here are the different parts of this line:

Hydraulic lifter: They are located below the unloading position of the hopper and are designed to automatically maintain the height of the top layer of the profile lifted from or into the hopper. The standard lifting capacity is 400 kg per unit. It includes photocells, electrical components and all hydraulic systems.

Setting from feeder to protector: Motorized roller conveyors are used to load profiles into the adhesive coater. The equipment includes a set of vertical rollers to center the profiles when they are loaded into the machine.

Film machine: The newly designed machine is designed to smoothly adhere the adhesive film to the top and bottom surfaces of the profile without creating air bubbles in the film itself. The machine includes a blade unit for cutting tape between one profile and the next without stopping the machine every cutting cycle. The newly designed blade unit ensures clean cutting without removing any overhanging tape.

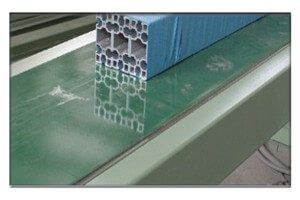

Belt conveyor over running: The belt conveyor is designed to automatically transfer the profile from the adhesive film coating machine. Belt material: anti-wear PVC

4 sets of cross conveyor belts: These belt conveyors are designed to automatically transfer profiles from the film production line to the packaging machine production line.

Belt material: wear-resistant PVC

Large spiral packaging machine: The machine adopts a compact steel frame design. Using the bayonet quick-change holder (for packaging material rolls), packaging materials can be changed quickly and easily (less than one minute). The contour is pulled out through the machine by a series of rollers, which automatically open and close, so that bundles of different sizes pass automatically without stopping the machine. The wrapping device consists of a rotor that rotates and maintains a roll wrapped with wrapping film, which is supported by a mandrel and has a specially designed clutch designed to maintain a constant tension before the roll is completed. These volumes can be easily and quickly replaced in less than a minute. The speed is controlled by an electronic inverter, which is controlled by a potentiometer located on the main control panel.

Taping machine: When the machine moves on the front and back sides of the profile, it will be stuck with tape without having to stop. It binds several spirals (binding loops) at the front and rear of each bundle to prevent the packaging materials from spreading. The profile can be programmed according to the speed of the packaging machine. It is mainly used for wrapping with paper or nylon, which is particularly easy to tear and unravel. When packaging with stretch film, the machine can be paused and switched to idle mode.

Outdated roller conveyor with automatic strapping machine: The machine is equipped with a pressure roller device, which is accelerated by a frequency converter. It completes the separation of the finished bundle, then stops at the correct position and aligns to form the bundle layer. An automatic device with a jack is used for strapping formation. During the production process, a special pneumatic device automatically winds a nylon rope between each bundle of profiled materials to prevent them from slipping off when moving. It superimposes them on layers and in this way produces bundles of the size selected by the operator on the main control panel.

Cross-chain transporter: These chain conveyors are designed to cross convey the stacked bales to the next machine after the automatic bale stacker.

The second exit roller conveyor: When manual stacking and packaging of profiles/sub-bundles is required, the second outlet is used to transfer the profiles to the manual packaging line; the machine includes a pneumatic pantograph to push the profiles onto the stacking belt.

Belt conveyor for traversing and crossing: These conveyors are used to transport the profiles/sub-bundles to the manual packaging line and are equipped with sensors at the end of the conveyor belt to prevent the profiles from falling.

Setting of the binding and unloading chain conveyor: These conveyors are used to load or unload bales onto the main chain conveyor leading to the strapping line.

Strapping straps: This machine is designed to use wooden blocks (upper, lower and side wooden blocks) to tie bundles of strapping pieces before shipment. The strapping machine itself is equipped with wooden block fixing devices for clamping the upper, lower and side wooden blocks during the strapping operation.