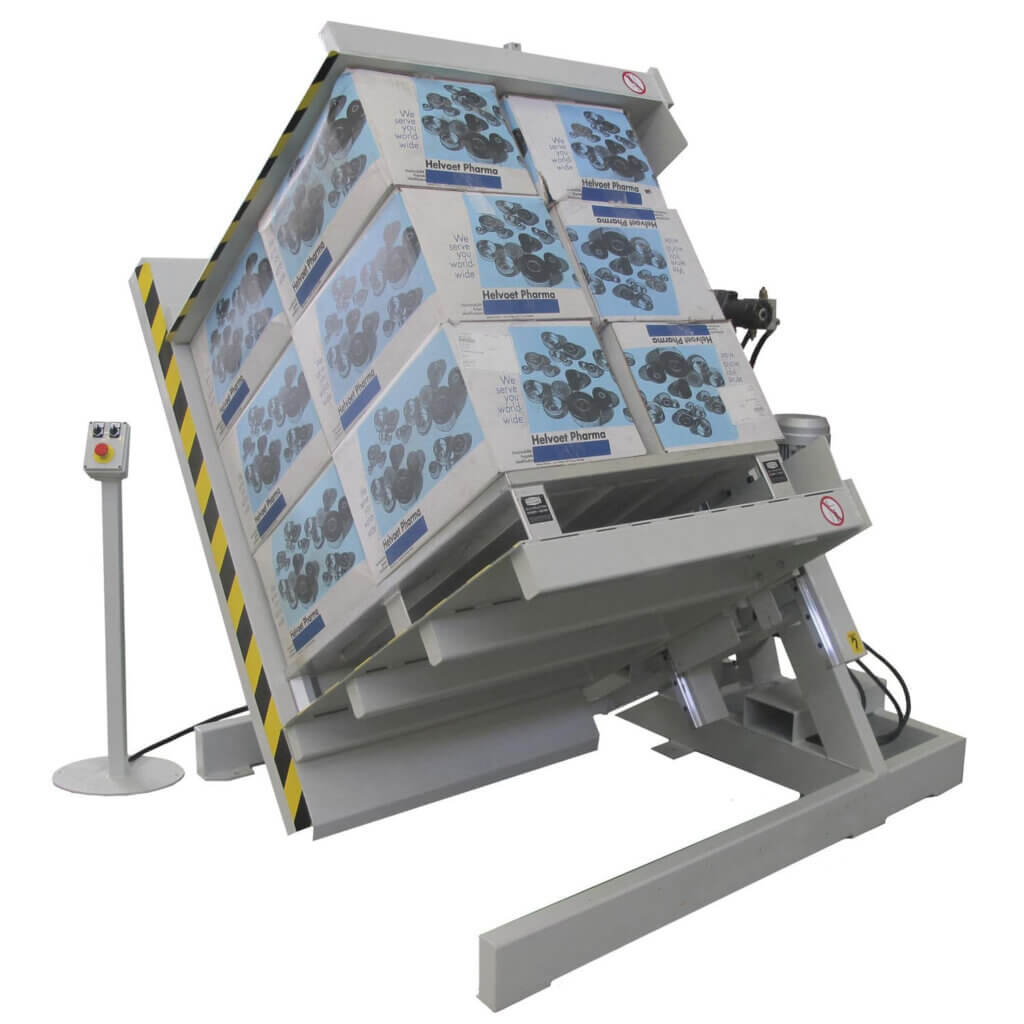

Pallet changer has been used in many different industries and often bring new possibilities to the logistics and warehousing automation upgrade. The pallet inverter usually use the clamping method or the push over method to do the work and some are using the turn and tilt methods for exchanging the pallets. The machines working with clamping methods is suitable for the desire of quick action and cheap costs, 50 times of pallet change is available by this machine.

It’s also optional to be automated for repalletizing the loads by upgrade the C shape pallet inverter with roller conveyors to reduce the unnecessary work. But the disadvantage of this kind of machine is they are suitable for robust goods not the sensitive goods.

Besides the clamping method, the overshifting method is an alternative method for repalletizing sensitive goods which including packaged foods or pharmaceutical products. By this method, the loads will be pushed onto a lower plate, make sure the action is totally safe for the sensitive goods. This special over-palletizing method is also can be used for the loads which are patchy or incomplete which by the clamping method it won’t be a good solution as the stability of that machine is low. This method can handle your load very gently and with a good capacity about 60 changes in each hour. Not matter it’s robust goods or sensitive loads, the overshifting method is always this efficient.

For your interest of choosing which pallet changer machine of which working methods, we are pleased to give advice to you based on your using application and the advantages of each method.

Pingback:Different handling methods of pallet inverter and pallet changer - Pallet inverter